There are a lot of popular workout routines trending right now from pickleball to cross fit, but no matter how you stay fit, you need the right equipment. While there are a few ways to make your own fitness equipment, most equipment calls for welding at one point or another. Many workout machines found in your local gym are welded from sturdy steel and can make great intermediate welding projects.

Here are 3 welding projects you can make for your own home gym or to sell to a local fitness center.

Flat Bench Press Welding Project

You can do a lot of lifting and up your fitness game on a basic flat bench press. The majority of the project is made from 4” steel square tubing with some other materials such as steel supports to ensure your bench can hold all the weight you’ll be lifting.

Start by making precise cuts and laying out your bench so you get a feel for the assembly. As you piece your project together, clamp your parts in place and add caps to your steel tubing as you go. For precise details for this project as well as measurements and tool requirements, check out these instructions from Craftsmanspace.com.

$10 Concrete Kettlebells Welding Project

Kettlebells are a great way to tone and train your body from top to bottom. If you’re looking to put your own spin on this versatile gym essential, we’ve got the perfect budget project, only $10! To create your own kettlebells you will need a bit of quikcrete, 1” rebar or steel pipe, small weight plates or scraps and a few other basics you’ve probably already got in your shop.

To start this project, take your hacksaw and cut 2, 10-12” sections, which will make up the sides your kettlebell handle, as well as 1, 7-10” section for the top. You’ll want to angle your side pieces slightly to increase the strength of your weld.

Next, take a deflated rubber ball and fill it with mixed quickcrete to form the weight of your kettlebell, set your handle deeply into your concrete before it dries. For more information on this project, click here for a detailed breakdown.

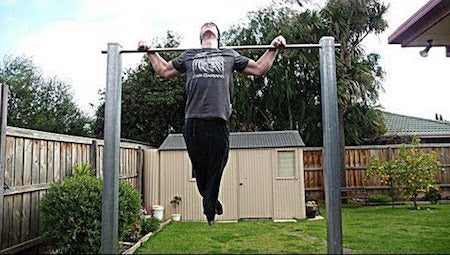

Pull Up Bar Welding Project

Ready to up your fitness game by adding a pull up bar to your backyard gym? For this welding project you’ll need digging equipment, welding gear, a post leveler, and concrete to ensure your bar is solidly grounded. The materials for this project are pretty basic, consisting of 2, 12 foot pieces of square steel tubing, a 5.5’, sturdy steel rod, and 2 galvanized post caps.

Start by securing your posts into the ground by digging two, four-foot holes, 5.5 feet apart in your backyard and setting them in place with concrete. Allow it to dry for at least 3 days and use supports right away.

Using a metal hole saw, cut through the posts creating a space for your pullup bar, weld the post into place on both sides of the post. Checkout this YouTube video for more information on this backyard welding project.

Hot Deals on Welding Projects at Baker’s

Before you beef up your home gym to amp up your fitness routine, head to Baker’s Gas and Welding to stock up on the machines, clamps, and safety gear you’ll need to get the job done. Baker’s carries all the brands you love like Tillman, Miller, 3M and more with promotions that can save you a bundle.