You can’t cut corners in TIG welding–or at least you shouldn’t if you want to get repeat business or you want your welds to look good. While it seems like the standard plan for TIG welding is to always go with Argon as your shielding gas of choice, there are some good reasons to listen up to the experiences of other welders about the shielding gas mixtures available. Here’s a brief overview of some shielding gas options to consider if you’re working on a TIG welding project:

Pure Argon for Tried and True TIG Welding

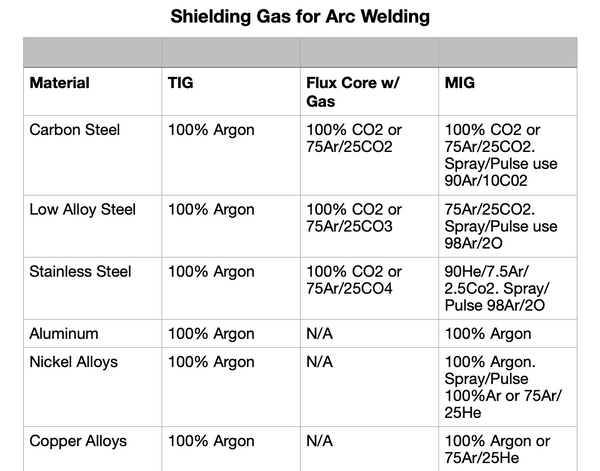

Welders have long relied on Argon for TIG welding because you can use it on every type of metal. As long as you’ve got the right electrode and settings in place, you can expect Argon to provide an effective shield for your weld.

The arc for a pure Argon shielding gas is narrow and concentrated so that you can get a precise weld with significant penetration. The outer areas of the arc will not heat up significantly while welding, and that means there’s a chance you could have some undercutting or bead rollover while you’re welding.

TIG Welding with an Argon Shielding Gas Mixture

Welders working with a Helium/Argon mix where Helium may be up to 50% of the shielding gas are able to enjoy significantly hotter welds while working. By adding Helium into the mix, you can give your amperage a significant boost.

Helium is used for most TIG welding jobs with the exception of mild steel. You can use it for aluminum, stainless steel, and copper alloys.

Helium does an excellent job of conducting heat and creates a wide heat profile that reaches the edges of the weld puddle. However, with the added heat come some challenges. For instance, you may need a high frequency TIG start to get going.

It will also help to increase your gas flow rate in order to ensure you’re protecting your weld puddle since Helium gas, even in this purified form, tends to rise up once released into the atmosphere. Of course, once you’ve jacked up the amount of Helium gas for shielding your weld, you’ll also want to make sure you’re not burning through your metal either!

TIG Welding with Hydrogen

In some cases, welders working with stainless steel may opt to work with hydrogen because it, much like Helium, increases the heat input while welding. Welders typically use 5% or less of Hydrogen in their shielding gas mixtures.

The advantage of Hydrogen for stainless steel is superior oxide removal and a hotter, wider bead that penetrates deeper into the metal.

Some TIG Welding Disclaimers

As you explore your own TIG welding setup, keep in mind that different projects may call for slight variations when it comes to gas mixtures. In fact, welders are hardly in agreement about how much Helium or Hydrogen you should ideally mix for an effective shielding gas. Check with your own gas distributor or message the team and Baker’s Gas and Welding with your questions.